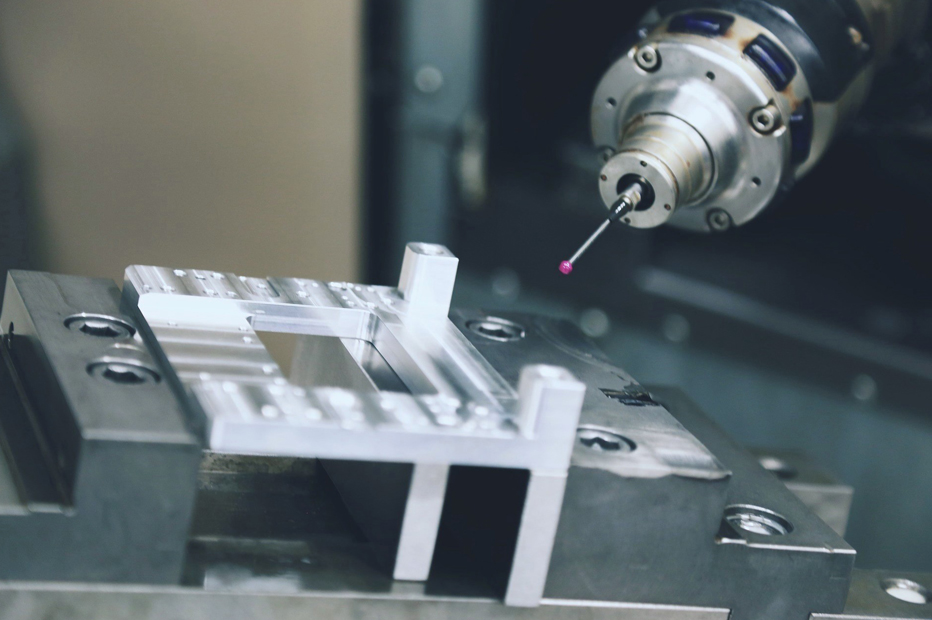

3D Water Jet Cutting

With waterjet cutting we add capacity, versatility, and flexibility to our business and your products. Its process of cutting materials by using a high-pressure stream of water can be used in various products.

For very hard materials, an abrasive is added to the water stream to increase the cutting power. Almost any material can be cut using a waterjet cutting machine. By offering a greater material variety and faster delivery times to our customers, we strive to differentiate yourself with our Resato 3D Waterjet!

Materials

Metals, including stainless steel, hardened steel, aluminum, copper, and titanium can be cut using waterjet cutting machines. Metals are formed with a crystalline structure which is tightly bound together by electrostatic forces. They have extremely high melting and boiling points. Metals are extremely versatile and are found in applications as diverse as construction, tools, cooking utensils, appliances, bolts, and automotive parts.

Metals are hard materials which require significant force or temperature to cut, but they can be deformed by the excessive heat generated by some cutting techniques (like grinding and machining). Waterjet cutting is an ideal technique to shape metal products without damaging the material.

The Water Jet may in addtion also cut other materials such as; Glass, Composites, Ceramics and stone to name a few.